| Number | Nature | Explanation | Action |

|

N3

|

Carburetter Specification Change

|

To meet recent U.S.A. legislation it has been necessary to introduce megaphone silencers modified to provide a lower noise level than the original megaphone type. The later type are modified by the fitting of a perforated tube in the end cone and their use necessitates the fitting of smaller main jets. The two types of silencer end cone are shown below:

|

Examine the megaphone silencer end cone. If this is hollow as the early type above, the jet size should be 220. If the end cones have a perforated tube as in the late type above, the main jet size should be 180.

|

|

N3/23

|

Cylinder head interchangeability

|

Introduction of the. current 32mm carburetter version of the standard Commando engine unit, replacing the previous 'Combat' specification (w.e.f. engine number 211110) has necessitated the introduction of two new cylinder heads which are listed below.

Interchangeability can be effected as shown, utilising the available range of cylinder head gaskets, in conjunction with the deletion of the cylinder base gasket where indicated.

Douglas Kane Loctite "Instant Plastic Gasket" is recommended for the cylinder base joint where NM24249 is deleted. Use H.M.P. grease for both copper cylinder head gasket joints.

|

|

|

N3/55

|

Introduction of rear chainguard extension

|

A new rear chainguard has been introduced on assembly subsequent to engine number 307091 which incorporates a detachable extension piece. The new chainguard 064837 is similar to the superseded part 061865 but incorporates two additional pierced holes into which the additional plastic extension piece locates.

|

1. To replace existing chainguard 061865 use the following components:

1 064837 Chainguard

1 064822 Chainguard extension

2 061823 Chainguard extension button

1 064824 Chainguard extension spring

2. To convert existing chainguard 061865 to accept and fit the new chainguard extension assembly, modify as shown below.

3. Stocks of the previous chrome plated rear chainguard 06122 with the rounded tail end are still available and can be obtained through the normal parts outlets.

|

|

N1/01

|

Kickstart foul on right exhaust pipe.

|

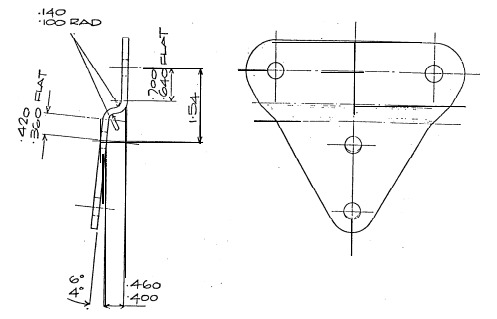

An alteration has been introduced onto the muffler bracket to provide adequate kickstart pedal operating clearance.

The new bracket, which should only be fitted to the right hand side pipe is supplied under part number 063579.

Alternatively the existing right hand bracket may be re-formed as indicated below.

|

|

|

N1/02

|

Alternative hydraulic hose lengths (disc brake)

|

It has been decided to make available alternative lengths of brake hose which can be ordered by distributors and made available at their discretion. Below are listed all the available hydraulic brake hoses with part numbers and lengths:

Standard hose 062707 Length 25in.

Alternatives

063508 23in.

063507 28in.

063541 31in.

063540 34in.

|

Where disc braked Commando models are equipped with alternative heights of handlebar, select the most suitable hose length from the list above.

|

|

N1/03

|

Availability of quartz halogen light units.

|

Quartz halogen light units are now available as a kit through the Spares Department to convert existing headlamp units. The conversion is available only for 7in. diameter headlamps and thus cannot be incorporated on Hi-Rider and SS models. The conversion kits available are:

Left hand dip set comprising:

54526114 Light unit

463 Bulb

553738 Bulb holder adaptor

Right hand dip set comprising:

54526323 Light unit

472 Bulb

553738 Bulb holder adaptor

|

Where quartz halogen light units are legally acceptable for your market, order the requisite number of conversion kits as normal spares requirements.

|

|

N1/04

|

Reproduction

|

To avoid production delays a Factory policy decision has been taken that in future main Distributors will be responsible for the reproduction and distribution of Service Releases. This will be done from text and, where necessary, artwork supplied from the Factory. The Factory will furnish main distributors with bulk supplies of headed paper to aid reproduction locally.

The reproduction method adopted is left to the distributor's discretion, dependent upon the length of his mailing list. It is most important to retain the Factory number sequence.

|

Advise Technical Department Wolverhampton, England, of the quantity of Service Release headings required and periodically call up further quantities as necessary.

|

|

N2/06

|

Crankshaft Main Bearings.

|

Field experience with 1972 models (incorporating two single lipped roller main bearings) indicates a small, but significant premature roller main bearing failure rate.

Reported failures have been confined solely to one type of bearing.

|

When replacing defective roller main bearings, ensure the replacement is a Skefco double lipped outer, single lipped inner spool type NJ306, with a specified nominal internal diametral clearance of 0.0008/0.0012ins. (0.02/0.03mm) Prior to fitting (180 Normal).

Ensure the crankshaft journals are carefully cleaned up, removing all signs of butts or scoring before fitting the inner spool. Models subsequent to Engine Number 207197 incorporate a nominal increase in bearing housing diameter to overcome any significant tendency to excessive closure of the single lipped outer series of roller bearings.

|

|

N2/08

|

Hydraulic Steering Damper Kit, Part Number 064247

|

Resulting directly from racing expcrience, and in acknowledgement of popular demand, an adjustable hydraulic steering damper kit complete with all attachment brackets, is now available through Norton Villiers spares channels.

The kit comprises a fully adjustable hydraulic steering damper, part number 064230 and mounting attachments as listed below, and can be fitted to all Commando models.

A fully illustrated fitting leaflet, part number 064629, is supplied with each kit, extra copies of which may be obtained for display purposes.

Note : The steering damper kit will be found particularly useful in restricting handling problems occasioned by crosswinds, rutted road surfaces, Grooved freeway surfaces, heavy touring luggage etc. It is not intended to rectify maladies in handling occasioned by incorrect maintenance, though an improvement even in these undesirable conditions may well be noted.

|

|

|

N2/01

|

Modification to exhaust valve guides.

|

The design of exhaust valve guide NMT2011 has been revised to prevent excessive oil passage between the valves and guides. The upper end of the guide has been shortened so that the taper on the valve stem cannot enter the neck of the guide which would cause a pumping action. To avoid reducing the supporting length of the guide, the lower end of the guide has been lengthened by a similar amount. The modified valve guide is being supplied against part number 063527, and as stocks are exhausted, the later guide will supersede the earlier type directly

|

Until dealer stocks of the taller guide are exhausted, ensure where possible that exhaust valve guides are used in pairs.

|